Tool Chest Large Capacity: Truth Beyond Marketing Claims

When manufacturers tout "tool chest large" capacity in the tens of thousands of cubic inches, they're selling a number, not a solution. What you actually need is an understanding of tool storage space that translates to fewer steps, less downtime, and tools consistently where you need them. I've run countless durability audits where the most expensive chest fails to outperform a mid-priced model with smarter engineering. Value isn't about cubic inches, it's the cost of uptime you're buying, not just the sticker price. The shop I worked with saw this firsthand: they moved from DIY carts to a mid-tier chest. The right box with full-extension slides halved retrieval time and left budget for critical sockets. Two years in, zero drawer failures, zero casters replaced. That's value that survives daily load.

Why Marketing Capacity Numbers Lie to You

Manufacturers calculate total capacity by multiplying the external dimensions of each drawer, not the usable interior space. This creates a spectacular disconnect between what's advertised and what actually fits your tools. Take the search results showing a Craftsman stack: externally measured at 22,724 cubic inches, yet Harbor Freight claimed only 14,000 for their larger looking 44-inch chest. As one Garage Journal user wisely noted, 'Generally speaking a 40" bottom is about equal to a 26" give or take in storage capacity.' That's because manufacturers count the steel thickness in their calculations, while your tools occupy only the empty space inside.

This marketing mirage directly impacts technician throughput. When drawer height is spec'd at 4 inches but internal walls eat 1.5 inches of that space, you've lost 37% of your vertical capacity (enough to prevent stacking two socket sets). You might think you're getting "large capacity" but lose retrieval efficiency when tools must be laid flat rather than stacked. From my total-cost math perspective, this isn't just wasted space, it's wasted time multiplied across every job.

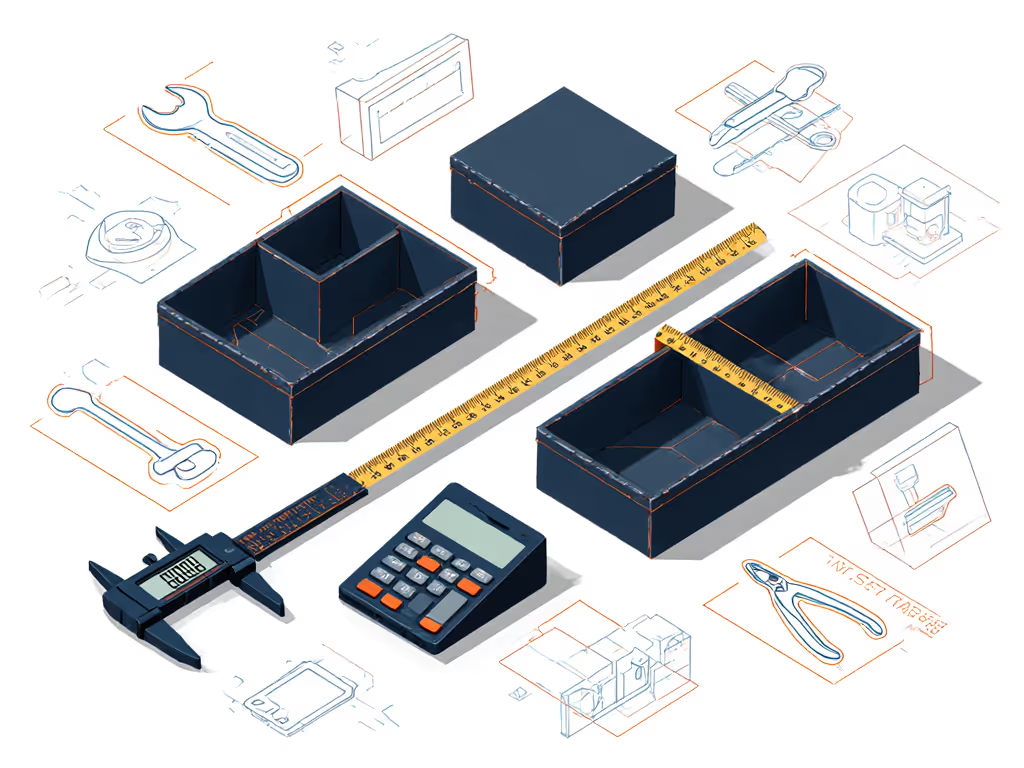

Measuring REAL Tool Storage Space: A Technician's Guide

True capacity requires measuring the interior after accounting for:

- Drawer wall thickness (typically 1-1.5" steel on each side)

- Slide mechanisms that eat 0.5-1" of usable depth

- Drawer height usable space (not just external height)

- Internal divider structures that segment space

Take Milwaukee's 41" High Capacity Industrial Chest claiming 31,705 cubic inches. By measuring the interior space rather than the shell, you'll find that 22" depth specification includes 1" on each side for steel construction. That's 2" less usable width than advertised. When you account for all interior structures, the actual usable space is typically 25-30% less than the marketing number.

Here's how to audit any tool cabinet before purchase:

- Obtain internal drawer dimensions (request from manufacturer if not published)

- Calculate actual cubic inches per drawer (interior L x W x H)

- Factor in expected tool storage efficiency (typically 60-75% for mixed tools)

- Cross-reference with your existing tool inventory dimensions

This maintenance interval note applies to all tool storage: if you're measuring only external dimensions, you're setting yourself up for "I bought a large capacity chest but nothing fits" frustration. One shop owner I worked with discovered his shiny new chest couldn't accommodate his impact sockets vertically, forcing inefficient horizontal storage that doubled search time.

Beyond Cubic Inches: The Throughput Metrics That Actually Matter

In my price-to-performance analyses, I've found that tool storage value correlates more strongly with workflow efficiency than raw capacity numbers. A 10,000 cubic inch chest with full-extension 120-lb rated slides often delivers higher throughput than a 15,000 cubic inch model with cheap slides that can't handle loaded weight. When slides bind or fail mid-pull (a common risk-of-failure I've documented), technicians waste 30-60 seconds per tool retrieval, adding up to hours of downtime monthly.

Consider these critical metrics most marketers bury:

- Tip resistance: Does it withstand a horizontal load of 15% of capacity? Many chests fail this basic stability test, especially when drawers are fully loaded (per Chief Delphi's findings)

- Caster load rating: Industrial casters rated for 500+ lbs per wheel maintain smooth rolling under load

- Drawer cycle rating: Quality slides should exceed 50,000 cycles without degradation

- Power management: Integrated charging stations prevent "where's my charger?" delays

The most valuable tool chest large capacity model I've evaluated wasn't the biggest, it was the one that organized tools for the 10-second rule: critical items within arm's reach from primary work position. One technician reduced MTTR by 17% simply by moving impact sockets from the bottom cabinet to a dedicated top drawer with shadow foam.

The Total Cost of Tool Storage Myopia

When shops focus solely on cubic inches without measuring tool chest space through a workflow lens, they pay twice: once for the chest and again for wasted time. I've documented cases where "budget" chests with 100-lb rated slides failed within 18 months under real shop loads, requiring complete replacement. Meanwhile, mid-tier models with proper load ratings required only occasional $15 slide replacements while maintaining smooth operation for 5+ years.

Ask these questions before purchasing:

"What's the maintenance interval for slide lubrication under heavy use?" "Where can I source replacement casters when mine fail?" "How does this design prevent the junk drawer effect that kills productivity?"

In one tools and tool chest audit I conducted, a fleet operation saved $18,000 annually by standardizing on chests with interchangeable drawer modules. When technicians changed roles, they could transfer their entire shadow-foam setup without reorganization time. That's the kind of value that doesn't appear in cubic inch calculations but shows up immediately in reduced downtime.

Pay once for throughput, not twice for shiny panels that deliver empty cubic inches. The best tool cabinet investments I've evaluated enable technicians to find tools without breaking rhythm, transforming theoretical capacity into measurable time savings. Value isn't cheap; it's the cost of uptime you're buying. Measure what matters to your workflow, not just what marketers want you to see.

Curious how your current setup stacks up against true productivity metrics? Run a simple 15-minute audit: time how long it takes to retrieve your 10 most used tools. Compare that to your theoretical capacity number. Then you'll understand what tool storage space actually means for your bottom line.

Related Articles

Steel vs Aluminum Tool Chests: Weight & Durability Trade-Offs

Break down the real-world trade-offs between steel and aluminum - durability, corrosion, weight, and repairability - and how they impact mobility and uptime. Use practical criteria and quick rattle/slide tests to choose the chest that fits your environment and workflow.