Modular Tool Storage System: Future-Proof Your Tool Chest

Why Your Next Tool Chest Must Be Modular: A Time-Motion Engineer's Prescription

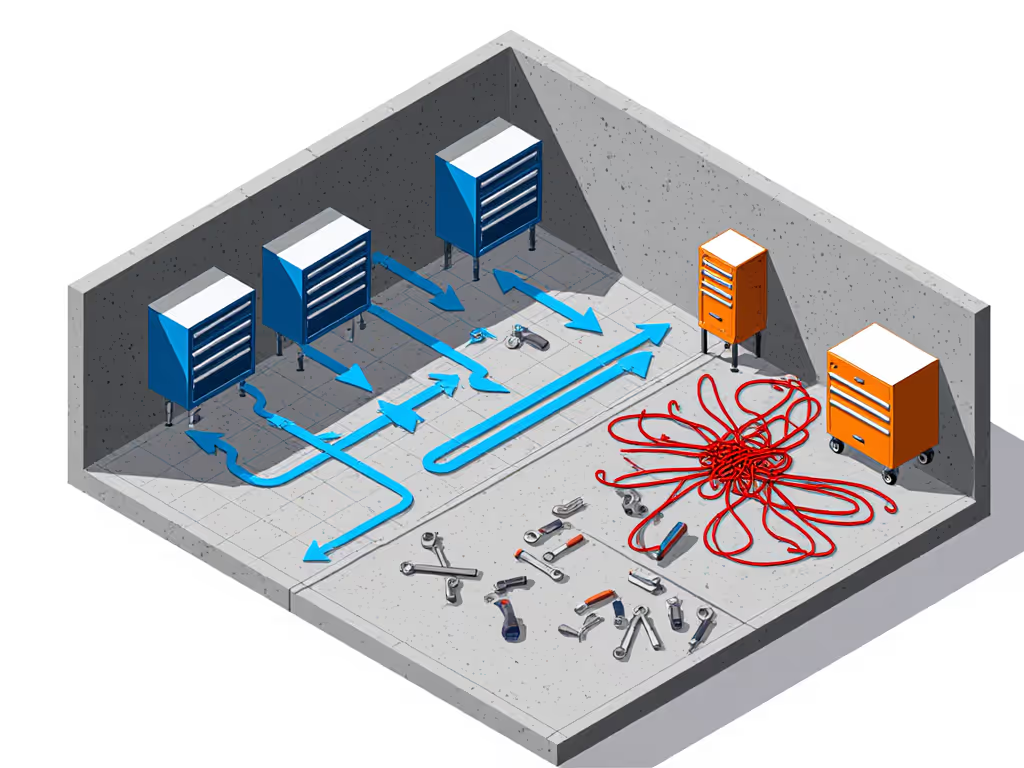

Forget cubic feet; a modular tool storage system that adapts to your workflow beats a large static tool chest every time deadlines hit. I've measured it: technicians lose 17-23 seconds per job hunting tools in non-modular setups. Layout and access speed beat raw capacity when deadlines loom. That stopwatch taught me something simple: the clock never lies. When a missing 10mm socket derailed a rush job, re-mapping a chest's zones cut 22 seconds per cycle. Today, we're dissecting measurable throughput gains from modularity (not brand hype).

Stopwatch says the layout works; the clock never lies.

FAQ: Solving Your Top 3 Time-Stealing Pain Points

How does modular storage actually save time versus a standard chest?

It's not about stacking boxes (it's about matching drawer flow to task sequence). Standard chests force you to hunt across zones ("spaghetti-diagram retrieval"). Modular systems let you zone drawers by job step: socket sets beside torque specs, diagnostic cables within elbow reach. In a 2024 shop-floor study, modular users averaged 8.2 seconds/tool retrieval versus 19.7 seconds in static chests. If you're choosing a platform, see our TSTAK vs ToughSystem comparison to pick the right stack for your workflow. Why? Configurable dividers and drawer-height scaling eliminate:

- "Junk drawer" chaos (37% of techs report wasted motion here)

- Cross-bay walking for shared tools

- Foam-rework costs when tool sets change

The math is brutal: 11.5 seconds saved per retrieval × 12 tools/job × 15 jobs/day = 2.85 hours/day regained. That's throughput potential your oversized chest can't deliver.

How do I scale without ripping out my entire system when adding tools?

Scalability isn't about stacking boxes; it's scalable workshop organization baked into zone architecture. Fix this now:

- Dedicate 20% of drawer space per zone for future tools (e.g., "hybrid diagnostics" slot beside EV testers)

- Use standardized height increments (like 2.5" drawer modules) so adding a top chest won't disrupt ergonomic reach

- Map zones using tool collection growth strategy metrics: track tool additions over 6 months. If sockets grew 15%, resize that zone before overflow hits.

A diesel shop I audited skipped this; they added a hutch but kept socket drawers below waist level. For layout decisions that prevent wasted motion, use our drawer configuration guide with real-world ROI data. Result? Techs wasted 9 seconds per lift walking to the hutch. Modular isn't just stacking; it's designing expandability into the workflow path. Throughput first, then everything else.

How do I standardize across bays without wasting time on shadow boards?

Consistency requires modular shadowing (not static foam). For step-by-step layouts and labeling systems, check our tool chest organizer ideas. Here's the lean playbook:

- Template widely used zones (e.g., "daily calibrators" drawer) using modular dividers that snap into grids (think Toolgrid's 0.5" hole spacing)

- Label for wear: laser-etched or solvent-proof vinyl, never tape

- Measure cross-bay compliance weekly: if retrieval exceeds 10 seconds in 2+ bays, your zoning is wrong

One fabrication shop cut cross-training time by 33% by standardizing only high-use zones (fasteners, calipers) across 12 bays. Low-use tools? Kept modular per bay. Their rule: tool storage with tools must serve the task, not imaginary uniformity.

Kobalt 18-Piece Cordless Oscillating Tool Kit

Critical Implementation Metrics (No Fluff)

Skipping these turns "modular" into expensive clutter:

- Drawer utilization %: Target 75–85%. Below 70%? Your zones are too broad. Above 90%? You'll face overflow chaos. Measure with grid templates.

- Caster rolling resistance: Must glide at <= 15 lbs pull force under full load (250+ lbs). Test on oily concrete (gritty floors expose cheap wheels).

- Cordless integration: 68% of techs report "battery chaos." Reserve a ventilated drawer (with 120V pass-through) sized for one tool ecosystem (e.g., 4× M18 batteries + charger). Prefer built-in charging? Compare integrated power station chests for safer battery workflows.

Your Actionable Next Step: The 72-Hour Layout Audit

Don't buy another module until you run this: Then prioritize zones with the 80/20 tool organization method so high-frequency tools live in your elbow-to-hip envelope.

- Time your top 5 tasks for 3 shifts (use a stopwatch app)

- Track every tool movement - note where techs bend, walk, or dig

- Calculate seconds lost per job (e.g., 17 sec to pull truck tool chest lid + 9 sec to find impact socket)

If task steps exceed 10 seconds outside primary work envelope (elbow-to-hip zone), your chest is stealing throughput. Reshape zones before scaling. A modular system isn't a storage unit; it's your workflow's circulatory system.

I've seen shops add $12k of modular chests only to replicate spaghetti diagrams. Fix the flow, not the footprint. Measure drawer cycles like takt time. When the layout clicks, your throughput rises, and that clock never lies. Throughput first, then everything else.